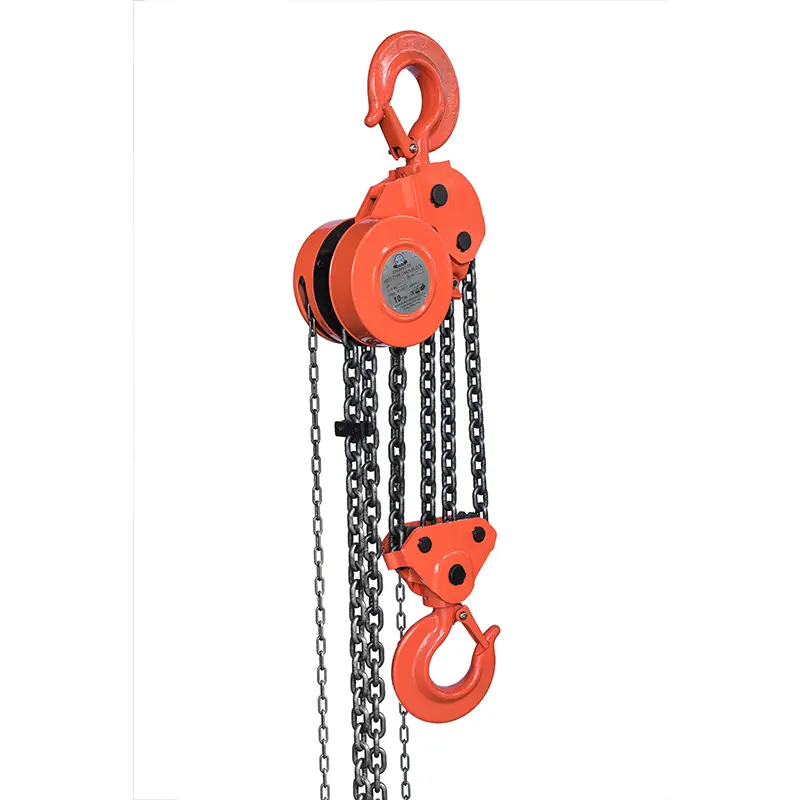

Structural principles and instructions for use of hand chain hoists

As an upgraded version of the fixed pulley, the hand chain hoist completely inherits the advantages of the fixed pulley. At the same time, it adopts the combination of reverse backstop brake reducer and chain pulley block, and has a symmetrically arranged two-stage spur gear rotation structure, which is simple, durable and efficient.

working principle:

The hand chain hoist rotates by pulling the manual chain and hand sprocket, pressing the friction plate ratchet and brake seat into one body to rotate together. The long tooth axis rotates the plate gear, the short tooth axis and the spline hole gear. In this way, the lifting sprocket installed on the spline hole gear drives the lifting chain, thereby lifting the heavy object smoothly. It adopts a ratchet friction disc type one-way brake, which can brake on its own under load. The pawl engages with the ratchet under the action of the spring, and the brake works safely.

The strength of the hand chain hoist depends on the details of the workmanship, and you also need to pay attention to some specifications when using it

Instructions for use:

1. Before using the hand chain hoist, you should carefully check to see whether the hook, chain and shaft are deformed or damaged, whether the pin at the end of the chain is firm and reliable, whether the transmission part is flexible, whether the braking part is reliable, and whether the hand Check whether the zipper slips or falls off.

2. When using, the hand chain hoist must be hung securely (pay attention to the allowable load of the hanging point). Check whether the lifting chain is kinked. If so, it should be adjusted before use.

3. When operating the hand chain hoist, first pull the bracelet back and relax the lifting chain to allow it to have sufficient lifting distance, and then slowly lift it. After the chain is tightened, check whether there are any abnormalities in each part and hook. Whether it is suitable and confirmed to be normal can continue to work.

4. Do not pull the hand chain diagonally or use excessive force. When using it in an inclined or horizontal direction, the direction of the zipper should be consistent with the direction of the sprocket to avoid chain jamming and chain dropping.

5.The number of people zippering should be determined based on the hoist’s lifting capacity. If it cannot be pulled, check whether it is overloaded, whether it is hooked, and whether the hoist is damaged. It is strictly forbidden to increase the number of people to pull the zipper by force.

6. During the process of lifting heavy objects, if you want to keep the heavy objects in the air for a long time, you should tie the hand zipper to the heavy objects or the lifting chain to prevent accidents caused by the self-locking failure of the machine if the time is too long. ACCIDENT.

7. The hoist must not be overloaded. When several hoists lift a heavy object at the same time, the forces must be balanced. The load of each hoist should not exceed 75% of the rated load. There must be a dedicated person to direct and synchronize the lifting and lowering.

8. The hand chain hoist should be maintained regularly, and the rotating parts should be lubricated in time to reduce wear and prevent chain corrosion. Chains that are severely corroded, broken, or streaked must be scrapped or updated and are not allowed to be used casually. Be careful not to let lubricating oil seep into the friction bakelite pieces to prevent self-locking failure.

9. After use, wipe clean and store in a dry place.